Maximizing ROI with PLC Automation: How to Measure Success

In today's fast-paced manufacturing and production industries, companies are increasingly turning to industrial automation to improve efficiency, reduce labor costs, and enhance safety. One of the key components of industrial automation is the Programmable Logic Controller (PLC) system, which provides real-time control and monitoring of machines and processes. In this blog, we'll explore the importance of PLC automation, as well as how to measure success and maximize ROI.

II. Understanding ROI in PLC Automation

Return on Investment (ROI) is a critical metric for any business investment, including industrial automation. ROI measures the financial benefit of an investment relative to its cost, and is calculated as the net gain divided by the initial investment. When it comes to PLC automation, there are several factors that impact ROI, such as equipment costs, maintenance and repair expenses, labor savings, and increased production capacity.

To calculate ROI for a PLC automation project, the initial investment should include all costs associated with the project, such as hardware, software, installation, and employee training. Once the project is up and running, companies can track the financial benefits of the project, such as labor savings and increased production capacity. By comparing the net gain to the initial investment, companies can determine whether the project has been financially successful and whether additional improvements can be made to further increase ROI.

III. Measuring Success in PLC Automation

To maximize ROI in PLC automation, it's important to identify key performance indicators (KPIs) to measure success. KPIs are metrics that help track progress towards specific goals and objectives. In the case of PLC automation, some relevant KPIs might include production output, uptime and downtime, energy usage, and maintenance costs. By setting targets and tracking progress towards these KPIs, companies can gain insights into how well their PLC automation systems are performing and make data-driven decisions to optimize their operations.

One of the benefits of PLC automation is that it provides real-time data on production performance and machine status. This data can be used to identify areas for improvement and to make data-driven decisions to optimize operations. By measuring and analyzing KPIs, companies can gain insights into how their PLC automation systems are performing and identify opportunities for improvement.

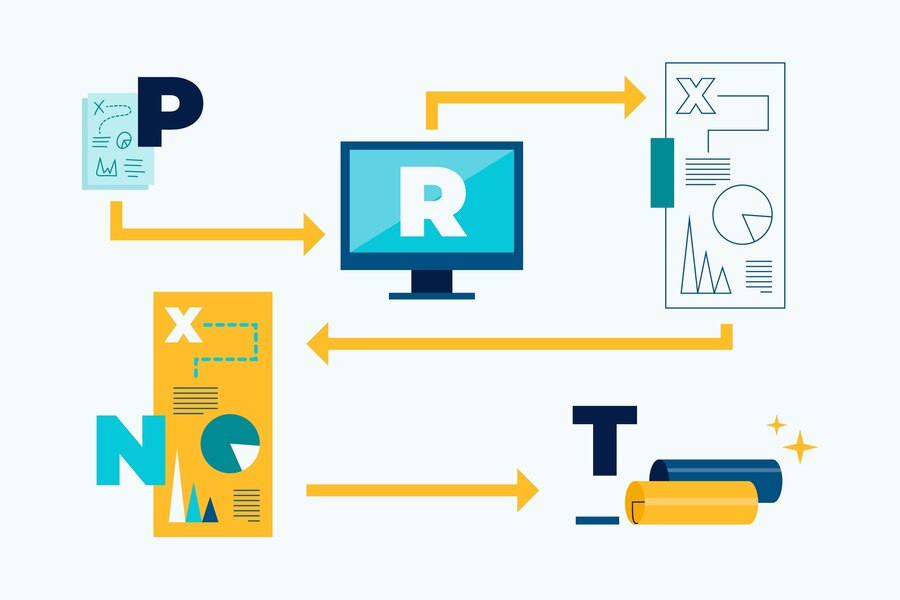

IV. Tools for Measuring ROI and Success

To measure and analyze data related to PLC automation, companies can use a variety of tools and software. For example, SCADA (Supervisory Control and Data Acquisition) systems can provide real-time data on production performance and machine status. Other tools, such as CMMS (Computerized Maintenance Management Systems), can track equipment maintenance and repair costs, while MES (Manufacturing Execution Systems) can provide insights into production scheduling and inventory management. When choosing a tool or software, it's important to consider the specific needs of the company and the goals of the PLC automation project.

V. Maximizing ROI with PLC Automation

To achieve maximum ROI with PLC automation, companies should consider implementing strategies to improve efficiency and profitability. Some best practices for optimizing PLC systems might include upgrading equipment and software, reducing downtime through predictive maintenance, and investing in employee training and education. Successful PLC automation projects have been implemented in a wide range of industries, from food and beverage to automotive and pharmaceuticals. By leveraging the power of PLC automation and measuring success through relevant KPIs, companies can improve their operations and achieve significant returns on their investment

VI. Conclusion

In conclusion, PLC automation is a critical component of modern industrial automation systems, providing real-time control and monitoring of machines and processes. Measuring success and maximizing ROI through data-driven decision-making and best practices can help companies achieve greater efficiency, productivity, and profitability. As technology continues to evolve, it's important for companies to stay up-to-date on the latest trends and innovations in industrial automation and PLC systems. By doing so,they can ensure that they are maximizing their potential for success and staying competitive in their industry. With the right tools and strategies, companies can achieve significant returns on their investment in PLC automation, while also improving safety and reducing labor costs. By tracking key performance indicators and continuously optimizing their operations, companies can stay ahead of the curve and achieve long-term success. Overall, PLC automation is a valuable investment for companies looking to improve their operations and stay competitive in today's fast-paced industrial landscape.

Comments

Post a Comment